Plate Condenser

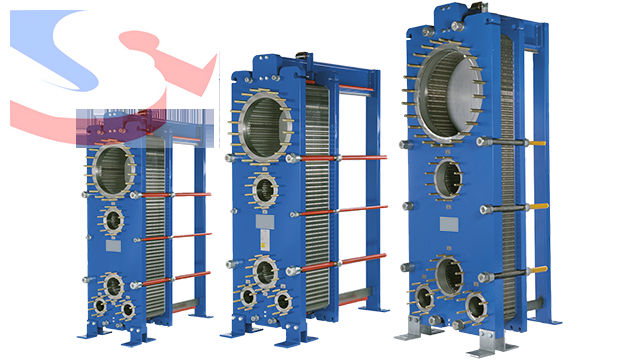

Plate condensers are specifically designed for condensing of vapours in low pressure or vacuum conditions. These plate surface condensers are ideal for applications such as vacuum condensers in evaporation systems, ethanol condensers in bioethanol plants, pan vapour condensers in sugar refineries and as turbine condensers in small power plants. With its compact design, it is easy to install where space is limited.

Highly Efficient Features

Plate Condenser Technology is an attractive alternative to the bulky indirect shell-and-tube condensers. Furthermore it is also suitable for direct condensing duties when condensate recovery is the goal and when space is a limitation. The Plate Condenser can be designed with or without sub-cooling of the condensate. Non-condensables are removed from the condensate outlet pipe and returned to the vacuum system.

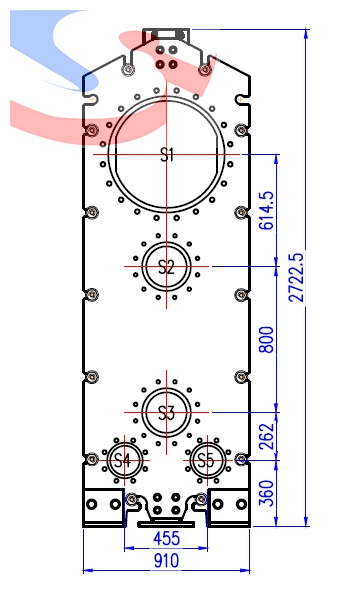

Compact Structure and Easy Maintenance

Plate Condensers are easily accessible for inspection and mechanical cleaning by removing the tightening bolts and rolling back the pressure plate. By adding or removing Plates the Plate Condenser can be modified to cope with changes in process conditions which with a Shell and Tube Heat Exchanger is not possible.

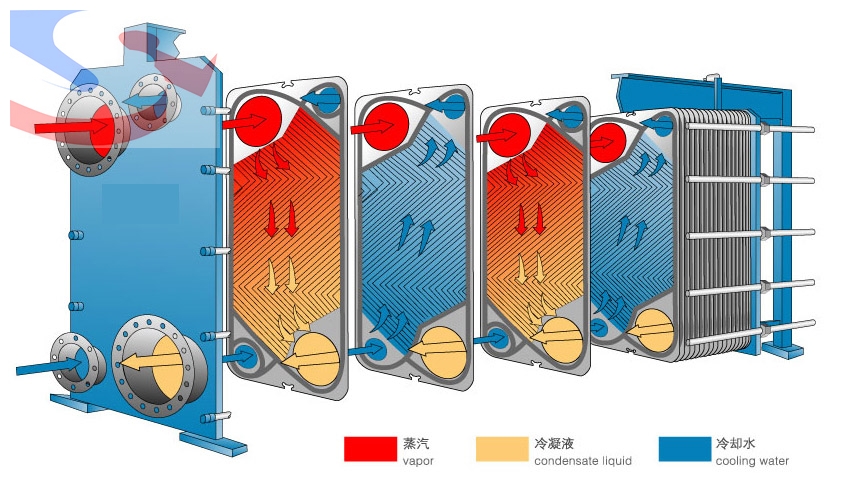

Working Principle

Similar to the Semi-Welded Plate Heat Exchanger, the sealing between the plates of the Condenser alternates between laser welds and gaskets. It has a unique porthole configuration that is specifically designed for low pressure / vacuum condensation. Vapour condenses in the welded channel and the cooling water passes through the gasketed channel.

The channel gap size is asymmetric with a larger gap on the vapour side and a smaller gap on the cooling water side. The result is a very low pressure drop on the vapour side and high velocity and turbulence on the cooling water side. Together, these features maximize heat transfer efficiency and minimize fouling.